inspection

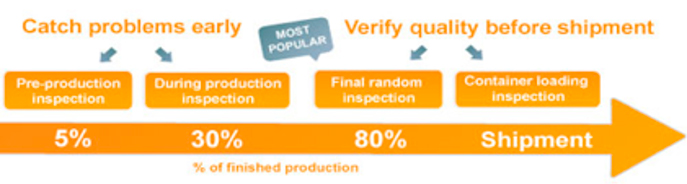

STANDARD QUALITY CONTROL STEPS FOR OUR INSPECTION

The following steps need to be followed by our suppliers and CMP QC-Teams.

1. VISIT / INSPECTION

The first inspection need to be done when the items is profiled and drilled.

1. VISIT / INSPECTION

The first inspection need to be done when the items is profiled and drilled.

- Check all items according to CAD drawings – this is very urgent for each order, so we are sure noting have been changed

- Check the quality of all items

- Check the hardware according to the signed master sample

- If the article contains glass – check if it’s temperate safety glass and check the colour according to master sample

- Assemble all article to check that it’s easy to assemble and according to master sample (if possible)

- Make a detailed report and send to CMP.

2. VISIT / INSPECTION

The second inspection need to be done when all items is ready painted / treated.

The second inspection need to be done when all items is ready painted / treated.

- Check the colour according to the signed colour sample / check the brand of paint/lacquer/stain and be sure the same as agreed are used.

- Check the quality of the items (poor sanding-scratches-press marks – poor machinery work – ) on the pallets – and select poor quality out for remaking

- Check that the hardware is packed according to the AI and CMP standard

- Assemble all article to check the quality in general according to master sample

- Make a detailed report and send to CMP.

3. VISIT / FINAL INSPECTION AND LOADING INSPECTION.

The third inspection need to be done when the articles is in packing line, or all are ready to be packed.

The third inspection need to be done when the articles is in packing line, or all are ready to be packed.

- Check that the articles is packed according to our step to step packing list

- Check measures and weight of all boxes according to packing

- Check all quantities according to the KO orders – also orders on spare parts

- Assemble the articles and check that the hardware is according to the aIl

- Check the assembled articles according to the signed master sample

- Check that the boxes is looking nice and well closed – check labels is placed correct – check the weight and the measures on all cll.

- Check that the container loading will be according to the loading plan from CMP (labels placed in the same direction and not mixed)

- Make the final report and send to CMP.